My Integral adjuster loses tension over time.

If this happens there are three variables that can cause it.

(1) External leak. By cleaning and tensioning your unit you will see, in time, oil leaking from some point.

(2) Internal leak. Usually after some time the seals can degrade and allow oil to leave the pressure system and return to the reservoir.

(3) Leaky valves.

In all three cases something is wrong. Whether it's been damaged or just wearing out, it is time for service.

There are two external seals that may wear and should be replaced sooner rather than later.

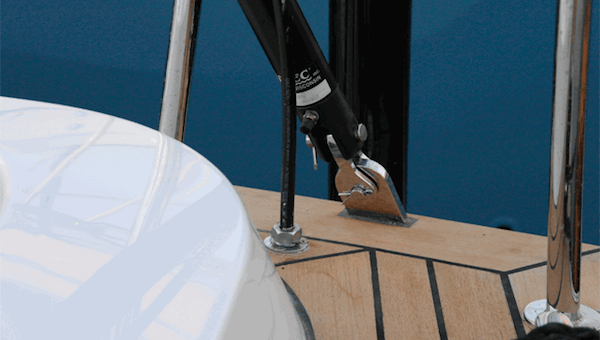

1) the wiper seal that sits on top of the cylinder and cleans the piston rod as it enters the cylinder.

2) the pump piston polypak is a seal that fits on the brass pump piston that goes in and out of the pump on every stroke. If that wears, an external oil leak is likely. Remember the oil is clear so check the deck below the bottom jaw (pump) occasionally.

These two seals can be replaced even if a full rebuild is not required. You may be able to do the replacement yourself with by purchasing parts from SAILTEC and following written instructions.

At the factory we find that an Integral is likely to require service / rebuild around 6 to 10 years. Maybe even earlier if the Integral is not used very often. The Integral will last longer if it is used. If you are not sailing regularly, make arrangements to have some one pump the Integral up and release tension once or twice every month. This pumping bathes the seals in oil to help them last longer. The seals last longer if the system is under some tension.

It is important to clean the outside of the Integral with fresh water and a mild detergent

regularly, weekly if possible. Equipment lasts longer with some easy maintenance. Some sailors use a light lubricant on the outside of the Integral.

If sailing is seasonal, you may wish to take Integral off the boat, store it upright in a clean location, a closet or garage. You may leave it on the boat if you choose.

The release valve is closed, and piston rod does not retract when pumped.

It does not work.

Was the Integral off the backstay and recently installed? Was the Integral unused for a period of time?

There may is an "Air Lock" where air is trapped in the pump which doe not allow for the check balls to seat properly.

Quick Air Lock Procedure.

Open release valve and pump the handle vigorously for two minutes.

Close the valve and pump the handle. If that does not work than try another

Air Lock Procedure (see section on Air Lock)

If the Air Lock Procedure does not work, call SAILTEC and discuss service options.

What size Integral do I need?

For each model Integral there are two sizes. "Standard," which is approximately 10" of stroke and "Long" which is approximately 14". Each model has a different pin-to-pin length and maximum tension.

Too many variables related to your rigging are involved for SAILTEC to advise you. Have a qualified rigger look at your boat to be sure and ensure safety.

Can I repair or rebuild my own?

Yes, but it is not recommended. Unlike some of our competitors, few, if any, special tools are needed. Parts can be ordered directly from SAILTEC.

It is not terribly complicated to someone with mechanical skill but the first one is a dozy. We spend two to four hours on a full rebuild. It will take you longer and then if it doesn't work correctly you may have to do it again or send it in to us. It is best to just have it done and warranted by us.

What is an Integral adjuster?

A hydraulic Integral adjuster is usually used as a backstay. It is basically a hydraulic cylinder with a pump and reservoir integrated into one package. It is a completely closed all-in-one hydraulic system.

All hydraulic systems are made of three components: a pump, a reservoir, and a cylinder. Oil is drawn from the oil reservoir by the pump. The pump forces oil into the cylinder forcing the piston rod or ram into the cylinder. This is the pulling force. Often the pump is a manual pump (which we call a panel) or an electric pump (which we call a power pack).

From this point, an oil line, capable of holding high pressure, runs to a cylinder. The pump moves pressurized oil into the cylinder to force the piston rod (or ram) to move and stay in position against tension. When the pressure valve is open on the pump the oil is allowed to return through this oil line and run through the pump back into the reservoir.

The Integral combines all these components in one piece. With an Integral adjuster there are no hoses running through your boat and the pump is a part of the cylinder so it is operated where it is used.

What is the locking option?

SAILTEC has a locking option that turns a hydraulic backstay into a mechanical backstay.

There is an additional cost however it works quite well and is invaluable in certain situations. (see section in catalog or web site regarding Locking Option).

What kind of maintenance is needed?

See section under Integral Adjuster Warranty and Owner's Guide: Periodic Review, General Care, and Procedure for testing (found on page three) elsewhere on this website.

How do I know it’s time for service?

If you're going on a long trip or if it's not working like it used to (this will be obvious to you). Review the maintenance procedures above. If it doesn't check out, it's probably time.

What’s the average turn around time?

Turn around time on rebuilt units is usually one to two weeks, door-to-door. To prevent delays, be sure to include contact information, with product, when sending it in for service. Also your authorization for a full rebuild, if necessary, will expedite the process.

I pump the Integral but the rod won’t retract fully.

It sounds like you're low on oil. A slow leak has likely developed. There are other possible causes. Please contact your rigger or SAILTEC to discuss your service options.

Can I add oil? How?

Yes, you can add oil, however, because the Integrals are zero leakage they are not designed to be easily tapped off. Sometimes a slow oil leak will develop and, over time, a major oil loss occurs.

Where can I send it?

SAILTEC manufacturers and services its own hydraulic products. Simply call and tell us what you have and what problems you need resolved. Then send it in with your contact information and authorization for service to be done. (SAILTEC, Inc., 2930 Conger Court, Oshkosh, WI 54904; 920-233-4242)

Do SAILTEC products work with Navtec hydraulics and rigging equipment?

SAILTEC continues to make Boom Vangs, Cylinders and Integrals designed to “slip-fit” into the Navtec product line with matching PCLC and Stroke. Some of the benefits of SAILTEC's products include:

- We match Navtec’s Pin to Pin Open, so you do not need to alter your Backstay Length.

- When comparing to Navtec, SAILTEC uses larger Piston Rods for added strength.

- SAILTEC’s Integrals will retract faster than Navtec.

- SAILTEC, like Navtec, offers Aluminum and Stainless-Steel material choices.

When replacing a Navtec product the key items to know are Pin to Pin Open Length, Pin Size(s) and Cylinder OD (outer diameter). Knowing the Navtec part number is also helpful. Call SAILTEC for assistance finding a replacement for Navtec rigging or hydraulics equipment.

The rod may stop short at approximately ½” closed, this is OK.

If the rod cannot retract most of the stroke then it may be low on oil.

If the Integral is low on oil, should I add oil?

You may add oil (see section on "Add Oil, Kind and Amount) however it is a tedious procedure and it is a short term solution. Before adding oil, inspect, clean and tighten all fittings, nooks and cracks.

Finding the cause of the oil loss and correcting it, is the best solution. It needs service.

I don’t use my gauge. Can’t I just plug it?

Yes, in fact, some people order them without gauges. Just replace the gauge with stainless steel pipe plugs. This is not true for top mounted gauges, which are much more prone to introduce dirt into the system, so please send to a pro.

"I pump the Integral up and it only pumps a little and then it won't pump any more.

The rod does not retract all the way, even with zero backstay tension. What is happening?

The Integral looses tension / pressure

Tension can change due to variation in air temperature. A few hundred PSI is normal.

If the tension changes, lowers while sailing a few hours, that is a problem.

Check for external oil leaks, especially at the lower jaw and/or at top of cylinder where piston rod comes out of the cylinder. (see section on Integral Test & Trouble-Shoot Check List & Periodic Review)

If the tension / pressure consistently does not hold for performance sailing, it is likely time for service. Call SAILTEC, 920-233-4242 or e mail, This email address is being protected from spambots. You need JavaScript enabled to view it. and we can help you decide what to do.

Can I add the locking option to an existing Integral?

It may be possible. Call SAILTEC to discuss that idea. There will be a loss of 1" of stroke.

The backstay has to be shortened to accept the locking option which is encased in an extension tube that makes it much longer.

How long can I expect a SAILTEC Integral to last?

SAILTEC builds hydraulics to last a long time. Our products are reliable and dependable.

There are some Integrals going strong at 20 years and some can wear out in less than five years. Our warranty is one year. Due to the quality of the metal uses in construction, a rebuild of the inside "softer" parts can extend the life of the hydraulics. A factory rebuild is approximately 1/3 the cost of a new unit.

Under normal operation, the aluminum, anodized finish, stainless steel and naval bronze components stand up against anything else on your boat. The seals (softer" parts) can be replaced when necessary. Having metal parts, an enclosed system, requires non metal external seals to prevent salt water, dirt and other contaminants from entering the system.

The Integral looses tension/pressure no matter how tight I turn the knob.

The knurled knob which controls the cartridge release valve (CRV) needs to be

"finger tight". Over tightening the knob will not affect the ability to hold pressure and may even damage the cartridge release valve.

I have a broken gauge. Can I get a new one and install it myself?

Yes, but it's tricky. Removing the gauge makes the system vulnerable to dirt. It's best to have a professional do it.

How does an Integral get low on oil?

As an Integral is a contained system, if it's low on oil that means there is an external oil leak, the oil is clear and even a small amount of oil loss over time will create a problem.

I can’t pull the piston rod out.

The release valve must is open. Is the valve stem, knob damaged?

Can you rotate / turn the piston rod? When trying to rotate the rod, is there on area where it is harder to turn? The piston rod may be bent if does not rotate freely.

Are you pulling the rod with enough force? When the Integral is new, everything is very tight and requires a lot of force. For example the smallest Integral, -08 needs 30 lbs. of pull to break away friction. A -30 needs over 200 lbs.

To manually gain purchase, remove clevis pins and thread a rod (a huge screw drive or metal dowel) through the clevis pin hole. Do this at the top end (Upper Jaw) and at the bottom end (Lower Jaw). You can plant your feet on the bottom dowel. This makes it easier to pull the rod out.

If the piston rod is "frozen" that is probably due to galvanic corrosion where the stainless rod "adheres to the aluminum cylinder. This happens when the wiper seal which sits on top of the cylinder and clean contaminates off the rod when it goes into the cylinder is

worn, cracked, extruded or simply missing.

This Integral needs service now.