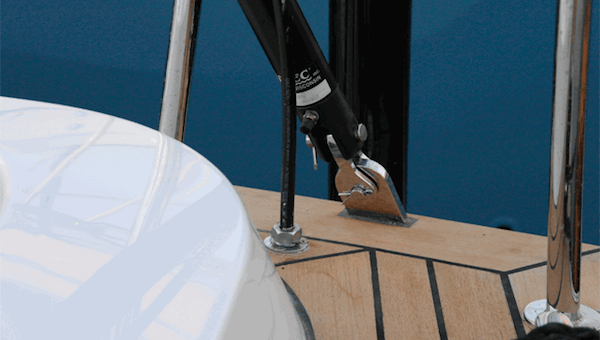

SAILTEC builds hydraulics to last a long time. Our products are reliable and dependable.

There are some Integrals going strong at 20 years and some can wear out in less than five years. Our warranty is one year. Due to the quality of the metal uses in construction, a rebuild of the inside "softer" parts can extend the life of the hydraulics. A factory rebuild is approximately 1/3 the cost of a new unit.

Under normal operation, the aluminum, anodized finish, stainless steel and naval bronze components stand up against anything else on your boat. The seals (softer" parts) can be replaced when necessary. Having metal parts, an enclosed system, requires non metal external seals to prevent salt water, dirt and other contaminants from entering the system.

Sail Faster with SAILTEC

SAILTEC, Inc. has specialized in designing and building hydraulic tension and rig control for sailboats and custom marine hydraulics since 1983. Our cost effective and durable hydraulic solution, coupled with a serious dedication to customer service and product support has made SAILTEC the first production boat source for many top sailboat brands for over twenty years.

We manufacture hydraulic/pneumatic cylinders, hand pumps, and 12V & 24V electric pumps that operate to 5000 psi (350 bar) and can generate up to 100 ton of force. Our latest products include hydraulic control of hatches, transom doors, swim platforms, keel lifting, radar lifts and other specialized applications.

SAILTEC is the sailing industry's preference for marine hydraulics offering:

- Worldwide sales and service

- Standard and custom cylinders

- Exceptional factory support

- Product innovation

Better performing products at a lower price, SAILTEC is a great value

- Light-weight cylinders and pumps

- Larger piston rods for longer life and resistance to side loads

- Redundant seals for extra leak prevention and longer life

- Faster pumping speeds than comparable models in the industry

- Competitive pricing

- Broad range of cylinders, integrals and pumps with respect to stroke, speed, fit and function