1) the wiper seal that sits on top of the cylinder and cleans the piston rod as it enters the cylinder.

2) the pump piston polypak is a seal that fits on the brass pump piston that goes in and out of the pump on every stroke. If that wears, an external oil leak is likely. Remember the oil is clear so check the deck below the bottom jaw (pump) occasionally.

These two seals can be replaced even if a full rebuild is not required. You may be able to do the replacement yourself with by purchasing parts from SAILTEC and following written instructions.

At the factory we find that an Integral is likely to require service / rebuild around 6 to 10 years. Maybe even earlier if the Integral is not used very often. The Integral will last longer if it is used. If you are not sailing regularly, make arrangements to have some one pump the Integral up and release tension once or twice every month. This pumping bathes the seals in oil to help them last longer. The seals last longer if the system is under some tension.

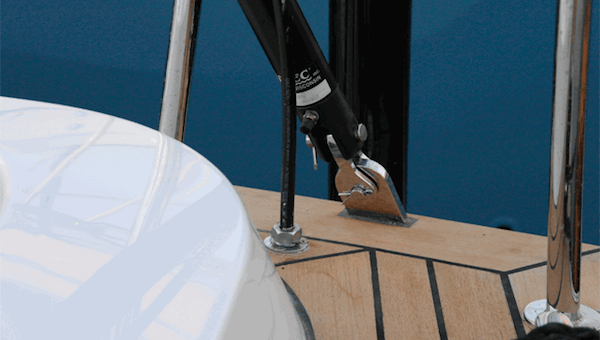

It is important to clean the outside of the Integral with fresh water and a mild detergent

regularly, weekly if possible. Equipment lasts longer with some easy maintenance. Some sailors use a light lubricant on the outside of the Integral.

If sailing is seasonal, you may wish to take Integral off the boat, store it upright in a clean location, a closet or garage. You may leave it on the boat if you choose.

The release valve is closed, and piston rod does not retract when pumped.

It does not work.

Was the Integral off the backstay and recently installed? Was the Integral unused for a period of time?

There may is an "Air Lock" where air is trapped in the pump which doe not allow for the check balls to seat properly.

Sail Faster with SAILTEC

SAILTEC, Inc. has specialized in designing and building hydraulic tension and rig control for sailboats and custom marine hydraulics since 1983. Our cost effective and durable hydraulic solution, coupled with a serious dedication to customer service and product support has made SAILTEC the first production boat source for many top sailboat brands for over twenty years.

We manufacture hydraulic/pneumatic cylinders, hand pumps, and 12V & 24V electric pumps that operate to 5000 psi (350 bar) and can generate up to 100 ton of force. Our latest products include hydraulic control of hatches, transom doors, swim platforms, keel lifting, radar lifts and other specialized applications.

SAILTEC is the sailing industry's preference for marine hydraulics offering:

- Worldwide sales and service

- Standard and custom cylinders

- Exceptional factory support

- Product innovation

Better performing products at a lower price, SAILTEC is a great value

- Light-weight cylinders and pumps

- Larger piston rods for longer life and resistance to side loads

- Redundant seals for extra leak prevention and longer life

- Faster pumping speeds than comparable models in the industry

- Competitive pricing

- Broad range of cylinders, integrals and pumps with respect to stroke, speed, fit and function